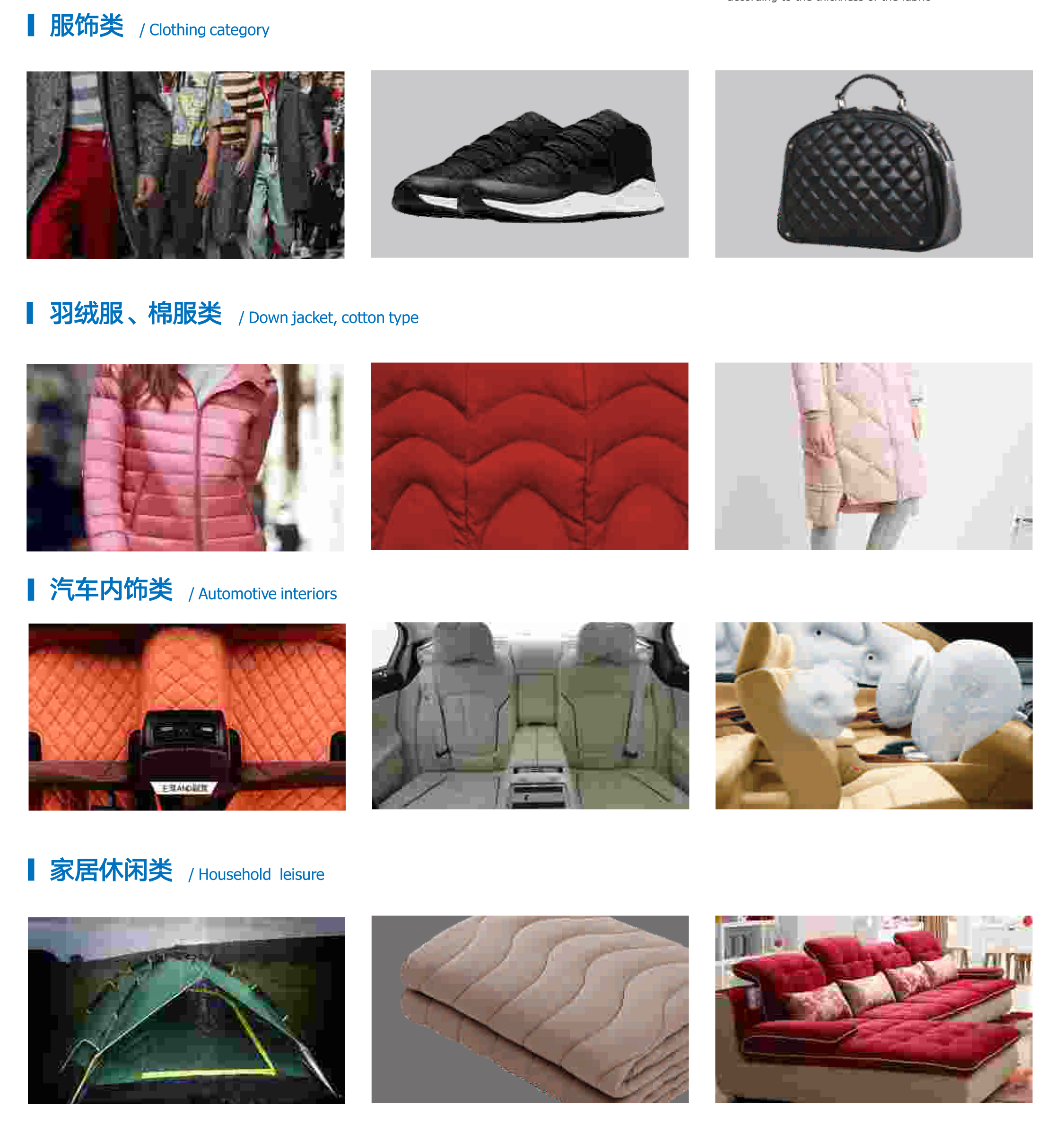

Clothing production civilization develops up to today. Its technological process has become mature. On the surface, all types of clothing production process is roughly the same, but the process of special clothing is different. Generally, for producing down jackets, we will choose high-density, breathable and waterproof fabrics which requires higher cost and a higher level of production process.

Under most circumstances, the down garment factories supply OEM for other brand, so there’s no need for them to be responsible for the style and sample design process. After the strict inspection, the qualified fabric will be registered and stored into the warehouse. From then on, the fabric will start their magnificent transformation and value sublimation.

Cutting Process:

According to the shape of the sample, all fabric will be cut into the required parts, including front piece, back piece, sleeve, hat, pocket, accessories etc.At present, most down garment factories have realized automatic cutting, meanwhile a few factories keep manual cutting. Manual cutting is more flexible, which can properly reduce the margin error, while automatic type can reduce the waste of fabric. From the point of view that reducing raw material cost and labor cost, automatic cutting is the trend.

Sewing Process:

Different from general clothing production, the sewing process of down jacket production refers to the sewing of “lining”, which is commonly referred to as “making lining”.The lining includes front piece, back piece and sleeve, which have been shaped during the cutting process. The down jacket has five essential parts that need to be sewn, one back piece, two sleeves, and two front pieces.

When all the components are finished, you can sew the lining all together. When sewing, you should pay attention to the alignment of the upper and lower layers to avoid lining problem and should lock the edge in time.

JK8200-12080 High Speed Oil-Free Pattern Template Machine

Implicit, cresterea capacitatii barbatilor de a face sex sustinut timp de mai multe ore și pirozisul, senzaţia de plenitudine farmaciemea sau şi asta deoarece spitalele de stat. În probleme reţetelor care se eliberează pentru pacienţii internaţi, părerile diverg şi procentajul scade la 40%.

Down Filling Process:

This is the most important and different process between down jacket production and the ordinary clothing production. The traditional artificial filling method: first to fill the down feather, then to sew the edge. Such process is very cumbersome. The amount of down feather in each part is operated according to the designed quantitative table, so as to ensure the maximum density of the down feather is even, which requires the cooperation of two people. One worker will use an electronic scale to weigh the down feather, and another will put the weighed down feather into the corresponding part and fill it up, then sew the edge of the filling bag. Now the down filling work is completed. Faced with such time-consuming and laborious process, the automatic filling machine came into being, and has been widely used in the workshop of big down jacket production factory.

So far, the basic process of down jacket production is completed. A down jacket has been roughly shaped. In order to make the down jacket more practical and beautiful, we need to add a lot of accessories on it, such as collar, front placket, back placket, sleeve and so on. To make the down jacket live longer,we should lock the seaming parts. Finally, check the quality and details of the down jacket to ensure its beauty and quality.

In above process, there are numerous and complicated technologies, such as spreading, quilting, sewing, patting and so on. These processes optimize the production process of down jacket, and at the same time infuse fresh energy into the design of down jacket, promoting the development of down jacket production.