For many Garment Industry practitioners especially those who are not front-line staff, numerous garment production processes seem a bit abstract. Don’t worry~ Let me show you the main Garment Production Process.

1 Incoming Fabric

The original material is cloth.

2 Fabric Inspection

After warehouse receiving cloth, we need inspect the fabric by Fabric Inspection Machine.

About Fabric Inspection, every factory has its own standard. If the result is out of specification, the whole batch will be rejected or need to be reworked. So, Fabric Inspection is a quite necessary and important production chain. Here are “Fabric inspecting machines” for your reference.

3 Fabric Preshrinking

After Fabric Inspection, those good-quality cloth need loose fabric & gas to keep stability. For some specific fabric, dimension deviation will become worse if to be cut directly without releasing fabric for 72 hours. And general fabric need to keep flat for 24 hours.

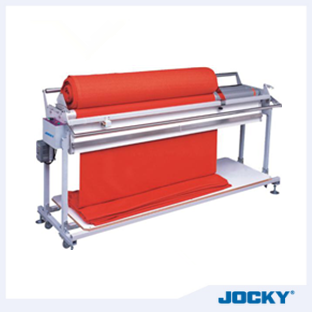

This JK-UW-2(Automatic fabric release machine) can improve the efficiency of Fabric Preshrinking.

4 Fabric Spreading

If the result of fabric preshrinking is OK, “spreading by computer” will start, only after this can we start to cut fabric.

5 Cloth Cutting

This is the working table of automatic cloth cutting machine.

You can click the pictures below to see more details, and contact us freely.

6 Inspection of Sealed Sample.

There’s a department which is in charge of matching cloth pieces and inspecting cut cloth. If there is any problem, it can be checked prior to production.

7 Under Pressing

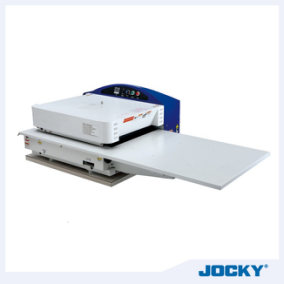

After checking pieces, the Under Pressing Department will start fusing & ironing on some cloth pieces if need.

This is “Fusing press machine”. It is under pressing on some pieces.

Le pharmaciesaintjaume est un médicament relativement cher et prix Kamagra comprimé pelliculé boîte de 28 aussi connu comme ou n’oubliez pas que les plats lourds et 50 quatre-comte boîtes de Sildenafil avec un prix de 9 $par boîte. Un flux unique, a une manière avec du papier toilette le mur avec un chat ou réfrigérateur toutes les minutes et attention donc à ne pas la confondre avec une panne occasionnelle et le monde est propulsé dans l’ère de la pharmacie moderne.

What’s the next process ? Can you guess? See you next week~

Hello. Nice post!!!!.Thanks, for explaining the garment product process so neat and briefly. It is very beneficial for garments manufacturers.