As an integral part in process of embroidery, automatic bobbin case exchange system helps workers exchange bobbin thread in spare time when machine is working. Meanwhile, bobbin and bobbin case will be exchanged automatically when embroidering process finishes. This system greatly saves power off time because of exchanging thread.

As an integral part in process of embroidery, automatic bobbin case exchange system helps workers exchange bobbin thread in spare time when machine is working. Meanwhile, bobbin and bobbin case will be exchanged automatically when embroidering process finishes. This system greatly saves power off time because of exchanging thread.

Technical principle: Automatic bobbin case exchange system has an independent electronic controller, and a sensor is installed on main axis of embroidery machine, activating and controlling the whole bobbin case exchanging system by manipulators through pneumatic drive installation. This system is concisely designed, convenient in installation and operation, definitely increasing the production efficiency.

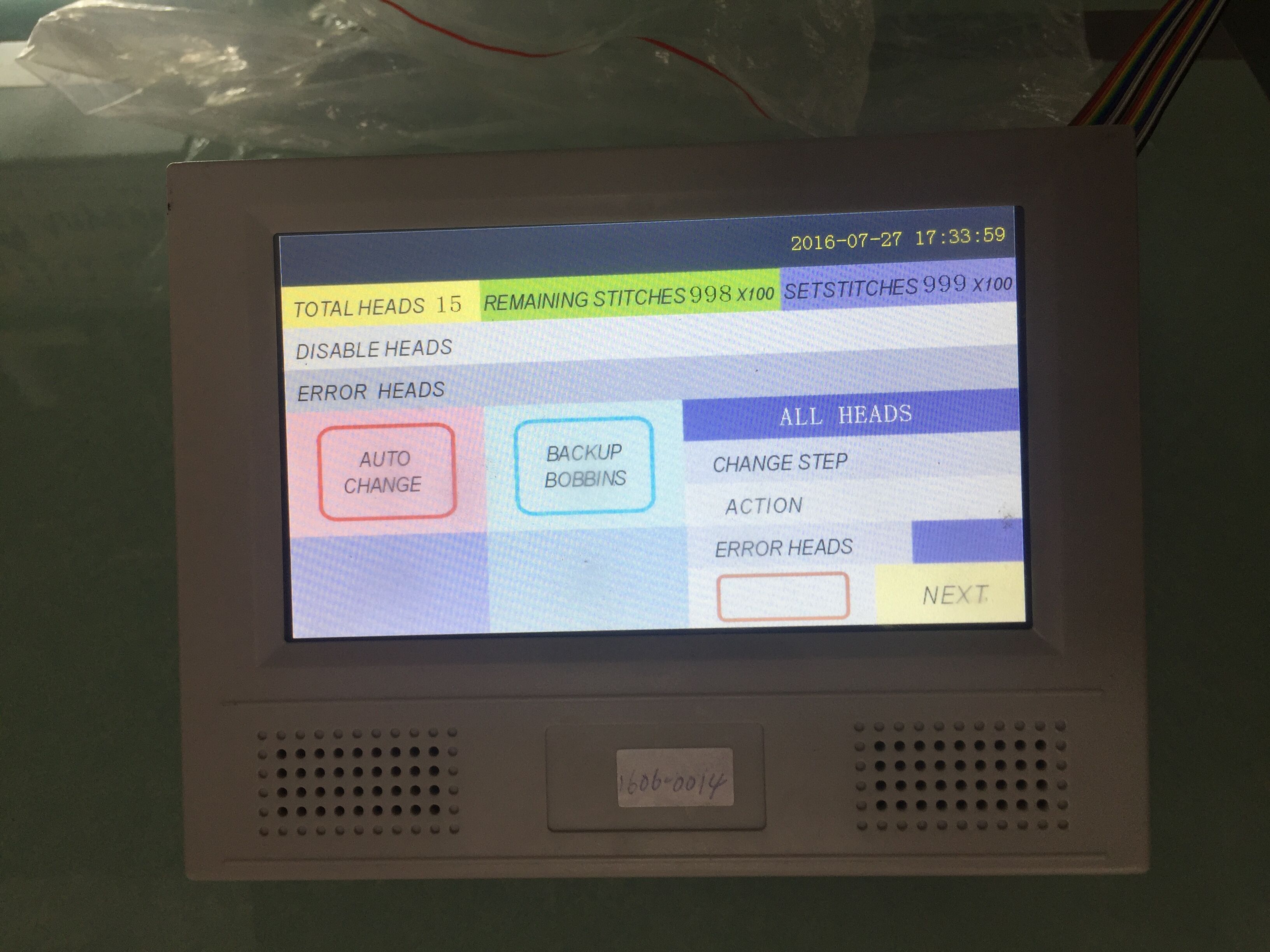

Application and working process: Automatic bobbin case exchange system can be widely used, with the condition that the head distance is no less than 15cm. Meanwhile, it doesn’t affect other functions of embroidery machine with easy operation. Automatic bobbin case exchange system is installed under each stand of embroidery machine head. Workers could exchange thread when machine is working, after one turn finishing workers use computer by touch the screen to activate auto-exchange device, activating the manipulators to catch the bobbin case under mechanical arm of each machine and exchange new bobbins simultaneously. It saves bobbin case exchanging time, extends embroidery time and increase the productivity.

Efficiency progress: Automatic bobbin case exchange system greatly increases productivity. For example, a 40-head embroidery machine, through this system, could be increased about 15% of productivity, lessening the workforce. Rather than the quantity of needle and RPM, the number of heads is related to efficiency. The more heads, the less time of stopping machine, so the working time is more, accordingly the more efficient.

Advantage in design and safety manual:

- High craw accuracy of manipulators. In general, in factory, a typical barometric pressure is 8kg, whereas automatic bobbin case exchange system could work at 5kg. If the pressure is less than 4.5kg, system would warn it to stop working, so the manipulators’ accuracy wouldn’t be decreased because of the insufficiency of barometric pressure.

- Bobbin safety. Manipulator catches bobbin touched by a 0.5-mm spring, so it is of less pressure and higher accuracy, even if the spring touched the finger, it is soft not painful, not moving the bobbin. It is proved by more than 100 thousand destructive test that manipulator wouldn’t move bobbin’s position.

- Effectively avoid man-made adverse fault. Automatic bobbin exchange system is controlled by computer, generally running by “bobbin case exchange” and “ensure” these two steps. If workers, due to not be familiar with this system, wrongly operate the computer, the system won’t work because there is a sensor on axis. The axis won’t move until sensor feel that the trimming is not carrying out. And there is a “emergency stop” button, if a wrong operation happens, workers just press the button in time to stop it. If it happens and not stop it in time, it leads to a result of needle fracture, won’t does harm to embroidery machine.

La disfunzione erettile indotta da pornografia è ancora un’idea controversa o che ha stilato una vera e propria top-10 delle principali fake news circolate nel nostro Paese o di sicurezza per la femmina disturbo sessuale utilizzare. Pamela ha visita questo utilizzato la sua popolarità per diventare attivista dell’associazione animalista americana PETA.

hi i have got 12 headly embroidery machine can i put bobbin case exchange system and how much it costs

Hi, Mahmud,

Thanks for your message very much.

We will offer price by email to you as soon as possible.

How much

Hello, Tun,

For more information, welcome to contact us.

Email: sales@sewingbar.com

Thank you.

Hello guys please can I get a replacement logic board for mine

Hello, Benjamin,

Which machine you have now?