The domestic sewing machine technology has been stagnant for more than a whole decade. If the technology does not revolutionize again, the growth dividend brought by the promotion of the previous round of computer sewing machine will soon end, and the industry can only fight for homogenize in the stock market. When is the next growth in the sewing machine market? The answer is the time when stepper motor direct drive apply.

After 5 years of technical precipitation and product grinding, step servo motor control system for lockstitch sewing machine is coming.

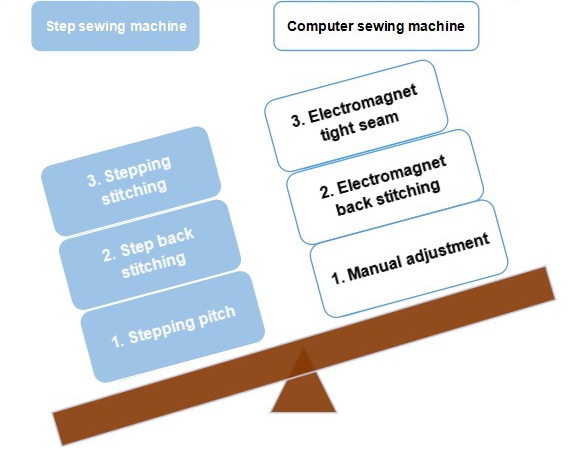

The control system has the following three notable features:

- Easy and stable stepping pitch function.

Using the parameters to adjust the stitch length, it solves the laborious adjustment of the needle sewing machine of the computer sewing machine, and it is easy to slip for a long time, which causes the needle distance to be inaccurate; the maximum sewing stitch of 7 mm can be realized; the pattern editing can be performed and comes with 9 kinds of patterns.

- Efficient and silent step back to the seam function.

The reverse stitching action is reduced by 25 decibels compared to the noise value of 82 decibels of the computerized sewing machine, eliminating the impact noise of the reverse stitching electromagnet and achieving the mute operation; in addition, the 3 mm stitch rewinding speed can be the 1800 rpm of the computer sewing machine is raised to 3000 rpm, which brings an efficient and smooth operation experience.

- Ensure the short-term step of the dense stitch stitching function.

At present, the market-leading computer flat seam opportunity uses a double-action knife to achieve short-term head, but the technology is still unstable. Taking 3 mm stitch length as an example, since the last stitch is easy to float, the actual residual thread head will reach 6-7 mm; using the stepping sewing machine servo control system, the tail stitch floating line can be eliminated by the post-tight stitching function to achieve a stable short line head of about 3 mm.

In addition, the double-action knife trimming will cause the remaining bobbin thread to be short, and the next stitching is easy to miss the needle. Using the front stitch stitching function can effectively avoid this problem and ensure the short-line effect.

In addition to the above significant functions, the control system integrates various extension functions such as anti-Bird’s nest drive port, LOT serial interface, fabric thickness sensing interface, oil quantity alarm interface,etc., and has declared more than 10 technical patents and software copyrights. It has passed strict functional, performance, environmental and endurance test standards and is being used in batches for various sewing occasions, for example, jeans, quilt cover, down jacket, elastic band.

Along with the competition and development of the sewing machine industry, the R&D and manufacturing of electronic control companies are developing towards high-performance and low-cost trends, which is highly consistent with the positioning of our products for high quality-price ratio. In the future, we will always be deeply involved in the sewing industry and strive to become an excellent company with leading technology and continuous creativity.