In our daily life, we seldom pay attention to the quality of single parts of sewing machines. Until the machine break down, we then start to take the parts quality into consideration.

Now we will give some tips to identify good parts from bad parts.

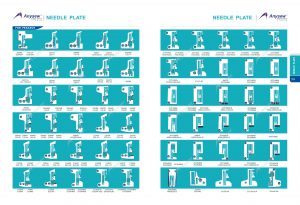

- The needle plate of mid-speed machines are all double-breasted, thus the latter half need to bear much more force. The needle always break while doing back-latching works. Once the needle break, the needle plate will be damaged as well. However if the quality of the needle plate is good enough, it won’t suffer from break needles. So how to test the quality of a needle plate? Let me tell you. Put the screw driver into the feed hole of the needle plate and then shake it. After that, check if the needle plate deformed or not after the shaking. Deformed, bad one; undeformed, good one.

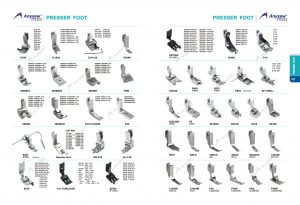

- How to identify good presser foot? Interlock it with a pliers. If there is no impress on the body of the presser foot, then it must be a very good one.

- In the industrial sewing industry, high speed machines are widely used. The fabric are always new water-proof material or chemical synthetic fiber. Thus the needle have to be able to withstand high temperatures. We’d better not to choose needles coated with Chromium. There seldom come out good works after using such needles.

- Beautiful polishing and fine non-burr tips of a hook plays a very important role in high speed sewing machine works. Bad hook will lead to unstable bobbin case. And you can feel much burr while holding it. What’s more, the tip is very fragile. All these causes would result in bad works.