Swing shuttle mechanism electric pattern machine threading mechanism formed with needle rod, machine needle, shuttle race, shuttle support, swing shuttle and shuttle race cover. There has shuttle support protect the needle when threading, passageway smooth and not blocked when threading off, obvious advantages at produce thick and hard fabrics, but it will caused thread blocked failure if problem at sewing threads quality, not adjusted bottom threads well and additionally error operation, so need adjust the threading mechanism again.

- Adjustment of needle rod height

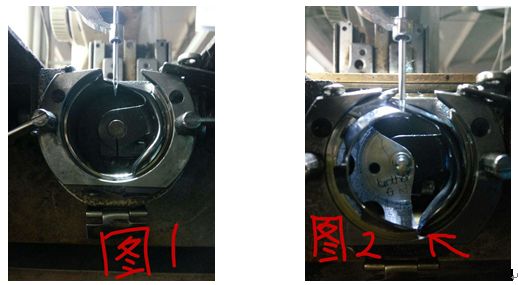

Needle rod drop to the down dead point position and using DP×17 machine needle, the second mark line of needle rod just exposed the down bush of needle rod. Shown as fig 1, able to produce one fix gauge with length from down bush of needle rod to needle board according to standard machine if meet incorrect down bush of needle rod position, unified the down bush standard of the same type machine; if meet incorrect down bush fix position of single machine then can refer to the fix position of other pattern machine, shuttle support almost at middle of machine needle hole when machine needle drop to down dead point. Need has clearance (1mm) between shuttle tail and swing shuttle tail when running, easy to broken threads if small clearance, it will send out noise (fig 2) if bigger clearance.

Fig1 Fig2

2. Adjustment of machine needle and shuttle protect needle clearance

Shown as fig 3, one hand rotate the hand wheel, thumb of one hand close to machine needle when machine needle drop to join with shuttle support protect needle, the thumb has tiny feeling when both join, now, this is the best clearance, means clearance is 0. If hand feeling the machine needle deformation then means smaller clearance, this will affect machine needle thread ring stroke. If no any hand feeling then means bigger clearance, no act performance of protect needle, this will caused rough threads, jump needle, even though damage the swing shuttle tip.

Fig3

Fig3

3. Adjustment of swing shuttle and machine needle threading time.

Firstly adjust the shuttle support protect needle to about 4mm exceed left end of machine needle when machine needle at down dead point, install swing shuttle, shuttle tip almost at center of machine needle threading platform (fig 4) when shutter tip rotate to machine needle center. Don’t adjust the threading time for the swing shuttle which trim shuttle tip to short, it will not tighten retrieve thread if advanced and change the threading off position, also will caused jump needle, no more performance of drop needle rod.

Fig4

4. Adjustment of machine needle and swing shuttle clearance.

The clearance when swing shuttle tip threading and machine needle clearance close to zero, the detail operating method is rotate the swing shuttle to threading position,fingers hole the swing shuttle core, left/right and font/back swing, hand feel the shuttle tip touch the machine needle threading platform, visual measure there no clearance then okay.

5. Repair shuttle support

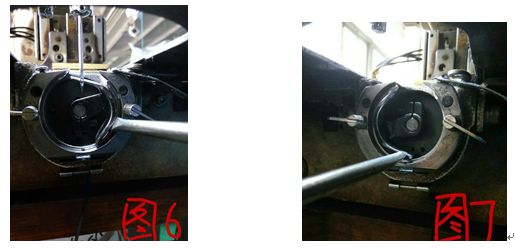

Use thick sewing threads, shuttle support easy to deform after machine blocked threads, arc come to be bigger after deformed, protect needle outward incline. The detail represents are that clearance between swing shuttle and shuttle support come to be bigger, shuttle support protect needle impact machine needle. Use screw driver insert into where between shuttle race and shuttle support when correcting, force to prize at shuttle support direction (fig 6). Prize to install the swing shuttle, the clearance between shuttle support and swing shuttle among 1~2mm, rotate handle wheel and check whether shuttle support protect needle still impact machine needle, if impact then use screw driver align to protect needle and use small hammer or handle pincers inward knock, till it accordance with standard (fig 7).

Fig6 Fig7

6. Repair swing shuttle, shuttle race cover and shuttle shell.

Machine blocked threads easily to damage the swing shuttle tip, unable to use if serious, if don’t want to discard it then can use argon-arc welding welded a section of damage part of shuttle tip by higher hardness steel wire, then repair well the profile according to size of new shuttle tip, the swing shuttle able to continue use like this. This publication already introduces in 2004, here not repeat it again. The contact part with swing shuttle will wear after long time use the shuttle race cover, make front and back clearance of swing shuttle come to be bigger, now able to place one piece water rub paper on the pane, drop a little oil, grind the shuttle race cover to be flat and calibrate the race contact surface. The shuttle shell and fix position handle which contact shuttle race cover will deform after long time use shuttle shell or blocked threads, this will caused threads blocked, able to use handle pincers repair and trim fix position handle, trim it till angular surface of shuttle shell handle and swing shuttle parallel then okay (fig 8).

Fig8