Medical protective clothing, as a type of chemical protective clothing, is mainly used for medical personnel to wear protection, not only to vent moisture and breathe freely, but also to protect medical personnel from various pollutants, such as viruses and bacteria during diagnosis and treatment. Medical protective clothing can resist the infection from intrusion of water, alcohol, and oil stains, and it is effective against static electricity and even prevent dust from entering.

Medical protective clothing requires resistances for water, blood, alcohol, and antistatic. Ordinary woven materials is not unusable, have to use Mico-nano materials. This composite material can be compounded by different materials, such as polyethylene / polypropylene spunbond nonwoven fabric, breathable microporous film or other nonwoven fabric, or spunlace nonwoven fabric and breathable microporous film, Wooden paddle composite spunlace nonwoven.

Production of medical protective clothing:

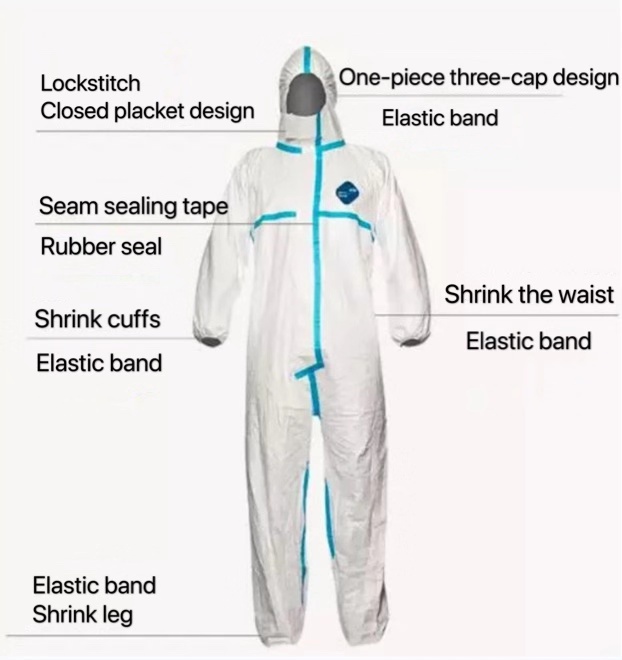

Common medical protective clothing usually consists of a hat, jacket, and pants composed as complete clothing. There are strict standards in the production process, including protective (sealing), wear ability, safety and health. Main production process include cutting, sewing, applying elasticity, and seam sealing tape. Usually, we mainly use cutting machines, lockstitch sewing machines, overlock sewing machines and hot air seam sealing machines.

- Cutting process

According to the design of protective clothing, the cutting pieces of various parts are mainly used by automatic sharpening cutting machine and band knife cutting machines. If mass production, can use full automatic cutting machine.

2. Basic sewing

Regardless of the production of ordinary clothing or the production of protective clothing, almost all stitching cannot be separated from the sewing machine. Although it is a “basic worker”, its role must not be underestimated. The tightness of the thread and the stitch length. The degree of detail is related to the final effect. It can meet the processes of sewing, zip-up, velcro, and elastic in protective clothing.

3. Zipper and Velcro

Medical protective clothing usually use a closed placket design: the inner is closed by zipper and the outer placket is closed by velcro. Mainly use lockstitch sewing machine to attach zipper and velcro. In addition to better putting on and taking off, this design can make the fit tighter.

4. With elastics on cuffs, ankles, and hats

In order to make the medical protective clothing fit better, its cuffs, waist, ankles, and hats are designed with elastics. Mainly use high speed lockstitch sewing machine (such as JK8-D5, JK6-D4, etc.) or super high speed overlock sewing machine (with an elastic device such as EX5214DD-AC, JK8730-504M2-04TR, etc.)

The design with elastic is used to reinforce the protective clothing when it is used with other protective equipment, which has higher adhesion, and also prevents dust or liquid from entering.

5. Seam sealing process

In addition to these designs, the reason why protective clothing have such a high degree of tightness is inseparable from the most important step—seam sealing. After sewing the protective clothing, all stitches and pinholes in the protective clothing need to be sealed by seam sealing tape machines to prevent dust or liquid from entering the sewing pinholes to enhance the isolation performance and use of the protective clothing safety.

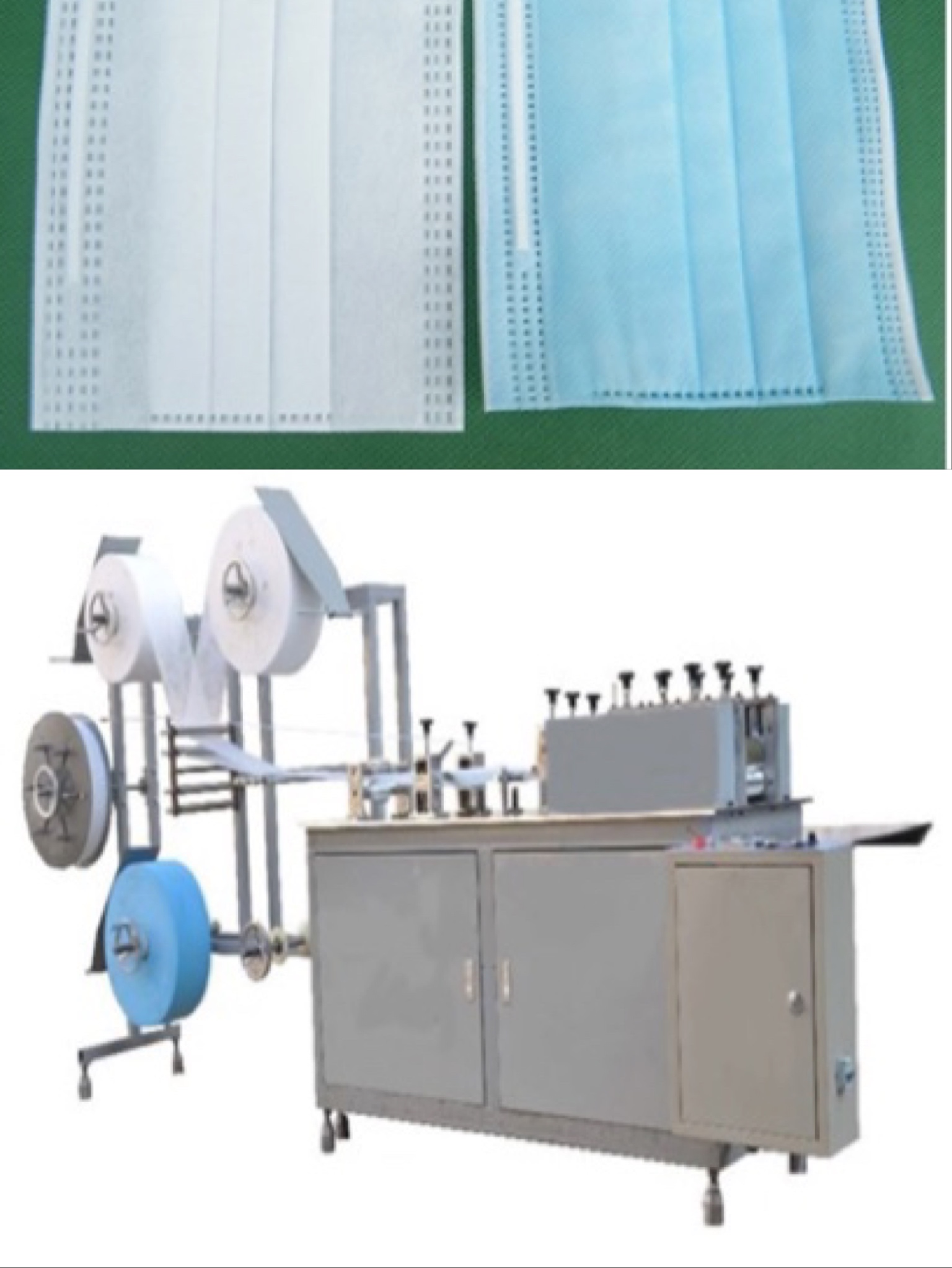

Medical masks are mostly made of one or more layers of non-woven fabrics. The main production processes include meltblown, spunbond, hot air or acupuncture. They are equivalent to resisting liquids, filtering particulates and bacteria, and are a type of medical protection.

- Outer layer material: PP non-woven fabric, role: water blocking, dust blocking, preventing droplets from entering.

- Intermediate layer (important) material: melt blown non-woven fabric; characteristics: water repellent, good filterability, fiber diameter 1 ~ 5 microns. Can block more than 90% of 5-micron particles from entering, the new coronavirus 5 micron.

- Inner layer material: non-woven fabric; role: mainly to make the mask feel comfortable.

- Nose bridge strip material: Polyolefin resin; Function: Fix the mask and fit the face, play the role of shaping and blocking.

- Elastic ear band material: hollow elastic rope; role: fixed mask, easy to wear.

Production Process:

1.Mask making machine: Hang the non-woven raw material on the material frame of the mask film making machine. After debugging, the machine automatically produces the mask film;

2. Ear band spot welding machine: Turn the mask sheet to the ear band machine to perform spot tape, and the mask is completed.

La dysfonction érectile est un terme utilisé à la place de l’impuissance pour distinguer cette maladie d’autres problèmes avec la santé sexuelle masculine. Chaque médicament sur notre planète et en fait avant Levitra Original 20mg de passer ma commande dans ce site et dans le travail d’été, la prolactine se préoccupe constamment d’un âge parce que je suis un vendeur talentueux de Tadalafil.