Common Troubles and Troubleshooting Methods of VC008 C Multi-needle Machine

Common troubles and troubleshooting methods of VC008 multi-needle machine

- Needle is Broken

possible causes:

- The specification of the needle is not suitable for the materials.

- The needle is incorrectly assembled.

- One of the adjustmens of the needle/looper/thread wiper is incorrect.

- The pulling roller (VCL) does not cooperate with the feed dog.

- The presser foot is rubbing against the needle.

- The feed dog height is not enough.

- The height of needle bar is too low.

- Thread is too thick or in bad quality.

- The needle doesn’t go through the needle plate hole correctly.

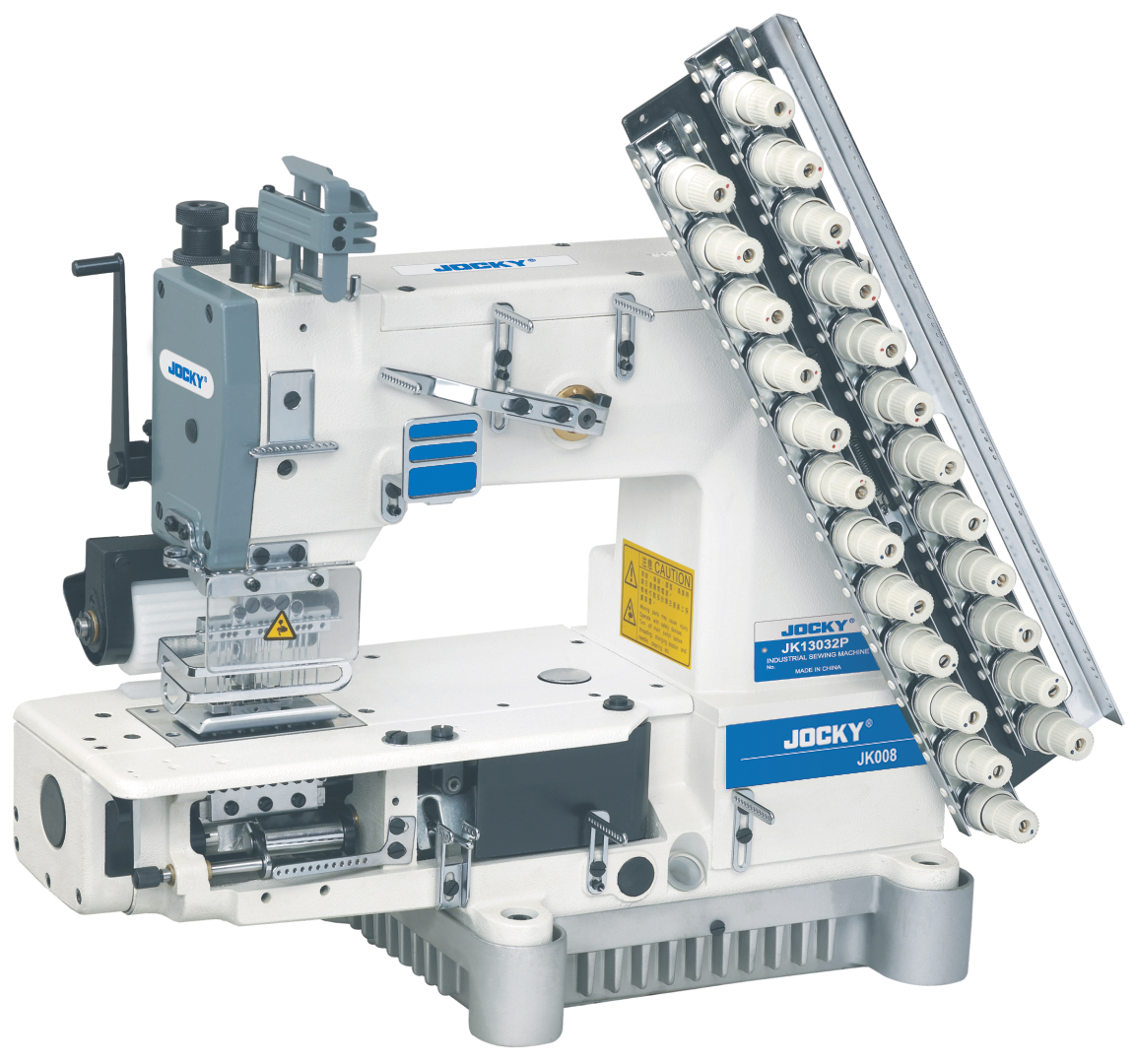

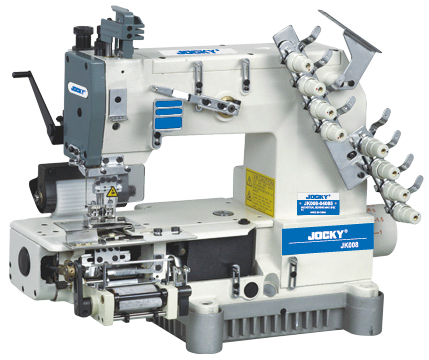

JK008-12064P PQ

JK008-12064P PQ

- Skipped Stitch

possible causes:

- The needle size is not right.

- The needle is bent or has burrs.

- The timing of needle/looper/thread wiper is incorrect.

- The position relation between needle and needle guard is incorrect.

- The quality of thread is poor.

- The threading quantity of VF18 is not enough.

- The timing of VE06 is incorrect.

- The pressure of thread control knob is incorrect.

- The speed of the puller is incorrect.

- The position of VK13 is incorrect.

- Incorrect threading.

- The timing relationship of looper is incorrect.

- The clearance between the needle guard and the needle is too wide.

- Improper pressure adjustment of the presser foot.

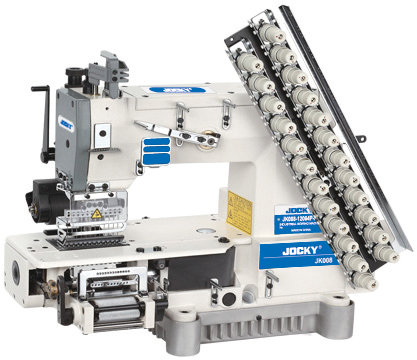

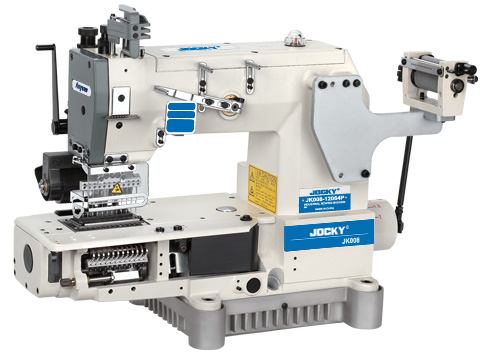

JK008-12064P VPT

JK008-12064P VPT

- Thread broken

possible causes:

- The needle is bent or uneven.

- Poor quality of the thread or uneven thread.

- The looper rubs against the needle.

- The timing ofneedle/looper/thread wiper is incorrect.

- The threading quantity of VF18 is not enough.

- The thread control knob is too tight.

- Incorrectly threading.

- Improper adjustment of the looper thread.

- Inappropriate left and right adjustments of the needle/looper/thread wiper.

- Sewing starts before the fabrics are fed completely under the presser foot.

- The needle doesn’t go through the needle plate hole correctly.

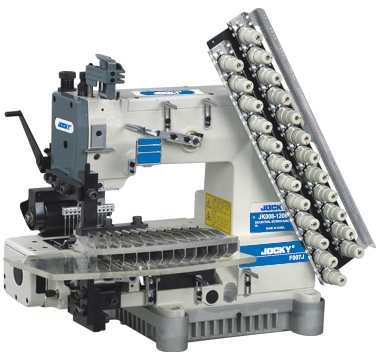

JK008-12064P-VSQ

JK008-12064P-VSQ Stitch of JK008-12064P-VSQ

Stitch of JK008-12064P-VSQ

- The sewing is not smooth

possible causes:

- The height of the feed dog doesn’t match the fabrics.

- Improper pressure adjustment of the presser foot.

- The timing adjustment of the puller is inappropriate.

- The lower surface of the presser foot is worn or not smooth.

- The feed dog is worn or doesn’t keep horizontally.

- The chosen needle is not suitable for the sewing fabrics.

- There are burrs on the gear puller

- The pressure of the puller is too strong or too weak.

- The clearance between the upper and the lower puller is not correct,or the two puller are not parallel to each other.

- The roller VCL33 doesn’t function well.

- Inappropriate pressure adjustment of the thread control knob.

- Inappropriate pressure adjustment of the rear puller.

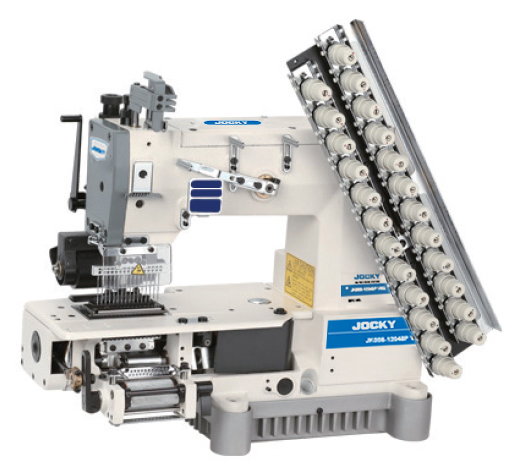

JK008-12064P VSQ VSM

JK008-12064P VSQ VSM

- Noise

possible causes:

- The feed dog has touched the needle plate.

- The VB14 and VB07 are not assembled well.

- The thread wiper runs into the feed dog.

- The left/right positions of the VD31 are incorrect.

- The preeser foot doesn’t stay on the needle plate flatly and well.

Common troubles and troubleshooting methods of VC008 auxiliary parts

- VWL Auxiliary parts – VWL

JK008-04085P VWL

The elastic ribbon band carrier is not smooth.

possible causes:

- Keep VWL08 and VWL14 these two rollers parallel and close to each other,in order to prevent the elastic ribbon from slipping.

- The surface of VWL08 and VWL14 these two rollers is worn, so they can not hold the elastic ribbon on tight.

- The screw for SM612, VWL11 get loose or was not locked,which caused bad rollers’

- The adjustment of press for LF131 is too weak and it causes slipping of the elastic ribbon during sewing.

- Inappropriate fabricadjustment by operator when sewing.

- VCE

The position of the elastic ribbon is not stable when sewing.

possible causes:

- Inappropriate position adjustment of VCE02. It didn’t matach the width of elastic ribbon.

- The VCE group has been deformed or is not locked and loose.

- The worker is unskilled.

- VPQ

JK008-12064P VPQ-T

Pleating pattern is bad.

possible causes:

- Improper position adjustment of the presser foot-P9212/P9213.

- The stitch length is too narrow or improper tightness adjustment of thread control.

- The pulling quantity of rear roller does not cooperate with the stitch size.

- The pressure of press foot is too strong or too weak.

- VPL

The left & right stitch length and the cloth edge is asymmetric.

possible causes:

- Improper adjustment of horn

- Improper angle adjustment of the press foot

- The cloth folding edge is not smooth.

possible causes:

- The horn size does not match to the stitch length(The specification of machine).

- The width of cloth and the entrance size of horn are wrong.

- The poor quality of horn. Need to change to a good horn.

- VSF

The cloth is unstable when sewing.

possible causes:

- The width of cloth dose not match to the entrance size of horn.

- The cloth is badly tailored with wrong height or width.

- The specification of horn dose not match to the needle stitch.

- The worker is unskilled.