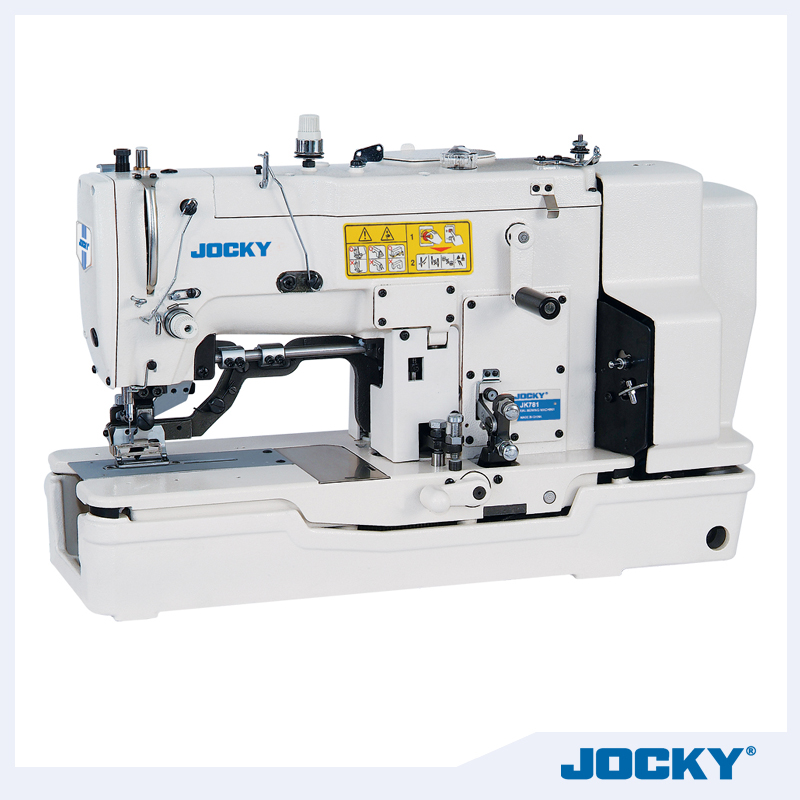

The different width of sides of JK-781 Straight button holing machine is not directly related to zigzag amplitude adjustment mechanism, but usually caused by screw improper adjustment. If there are loose parts inside, then they tend to make the left and right course problems simultaneously. Therefore, if one want to overcome this failure, only to analyze the reasons which affect the needle bar at the left seam row of the left limit needle position on the line.

The different width of sides of JK-781 Straight button holing machine is not directly related to zigzag amplitude adjustment mechanism, but usually caused by screw improper adjustment. If there are loose parts inside, then they tend to make the left and right course problems simultaneously. Therefore, if one want to overcome this failure, only to analyze the reasons which affect the needle bar at the left seam row of the left limit needle position on the line.

Needle bar drive the needle right and left to swing by forced. The needle bar frame is mounted on the machine head with a hinge pin, and then the lower part of the head caught a sliding needle bar to prevent needle bar frame around loose, but also to ensure the needle bar frame left and right swing easily. Then first let the machine in working condition when the row seam left, then gently turn the pulley, watch the needle on the left and into the left seam row limit position, take care whether it has phenomenon of heavier rotation or not. Then you can loosen the screws fixing spacer, move the spacer trace gently towards yourself, then turn the last round, to see if this phenomenon persists.

In fact, most of the problems happen here. Because the spacer installed too tightly or too much garbage inside caused. If this phenomenon persists, you can remove the needle bar frame, check the front crank swing to the left limit position then observe whether the touch phenomenon happens or not, to check whether the positioning screws is loose or not. After processing the above problems, the failure will be excluded.