The development of garment industry has been into a new level which thinks highly of quality and variety. Consumers require more to garments technique, so the survival garments manufacturers must be those who are committed to quality. The reason why most of our garments do not get popularity is not the design, but the quality and technique.

The development of garment industry has been into a new level which thinks highly of quality and variety. Consumers require more to garments technique, so the survival garments manufacturers must be those who are committed to quality. The reason why most of our garments do not get popularity is not the design, but the quality and technique.

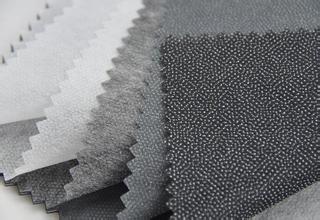

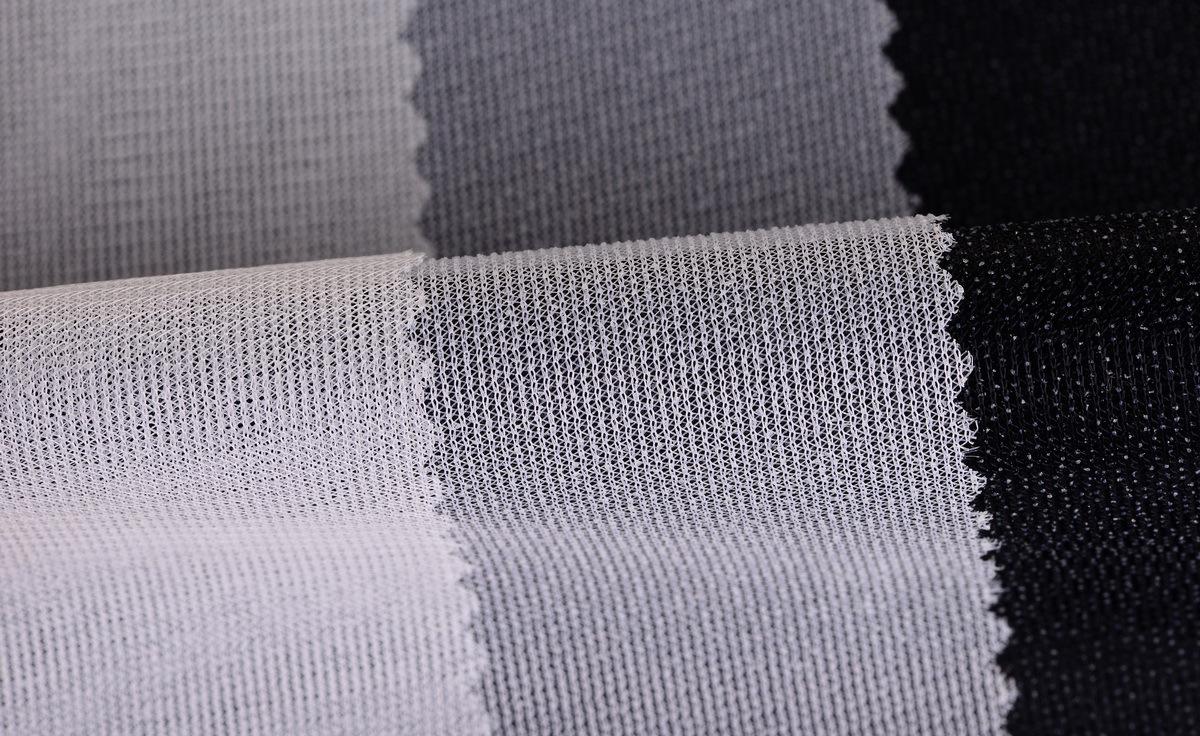

Interlining——also called Fusible interlining, is a lining fabric which is made by spreading the fusible melt on backing. It is invented in British in 1952, greatly developed since 1965, and used in China in 1980s.

Fusing and bonding process is a pretty important technical part in garment producing, also the part which is frequently of quality problem. Therefore generally garments factories usually use fusing press machine in order to guarantee the quality.

Hot fusing adhesive polymer could be bonded on fabrics; meanwhile the bonding strength is very ideal. Because there are many explanations about the fusing principle, so many fusing theories have been come up with. Among them, the most talked one is the diffusion bonding theory which is produced by fusing theory and physical and chemical effects.

Another theory is mechanical bonding theory, which said the reason of the fusing and bonding between lining and fabric is that fusing melt melting and then bonding with fabric during the process. Its bonding strength depends on the touching area between adhesive particle and fabric. Otherwise, diffusion bonding theory points that bonding is produced under a certain temperature, when hot fusing melt and fabric molecule moves fast, and penetrate into each other, leading to a result of bonding.